A non-conventional machining technique called electrical discharge machining (EDM), also known as spark eroding, spark machining, die sinking, wire erosion, or wire burning, removes electrically conductive materials using the thermal energy (melting and partial vaporization of the workpiece) produced by a series of sparks that occur between the electrode and workpiece. Materials with a range of hardness, complicated forms, strength, temperature resistance, fine surface smoothness, and precise dimensions may be machined effectively using the EDM method. The procedure relies on no physical touch between the tool and the work component. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At B&B Precision Wire EDM, Inc., we take pride in delivering cutting-edge EDM solutions that redefine precision and efficiency. With a relentless commitment to excellence, our team crafts a diverse range of EDM products that cater to the evolving needs of industries worldwide.

AMI Machining, Inc. takes pride in our unwavering commitment to excellence in the realm of Electrical Discharge Machining (EDM). We have consistently been at the forefront of innovation and precision in the manufacturing industry.

Conventional electronic discharge machining and wire EDM machining take place here at Aerospace Techniques. We machine items that are "out of the norm" due to complexity, material or shape. Since 1965, our machining services have been used for aerospace, aircraft engine and medical customers. Contact Aerospace Techniques today to get a quote for your next project!

More EDM Machining Companies

Working Principles of EDM Machining

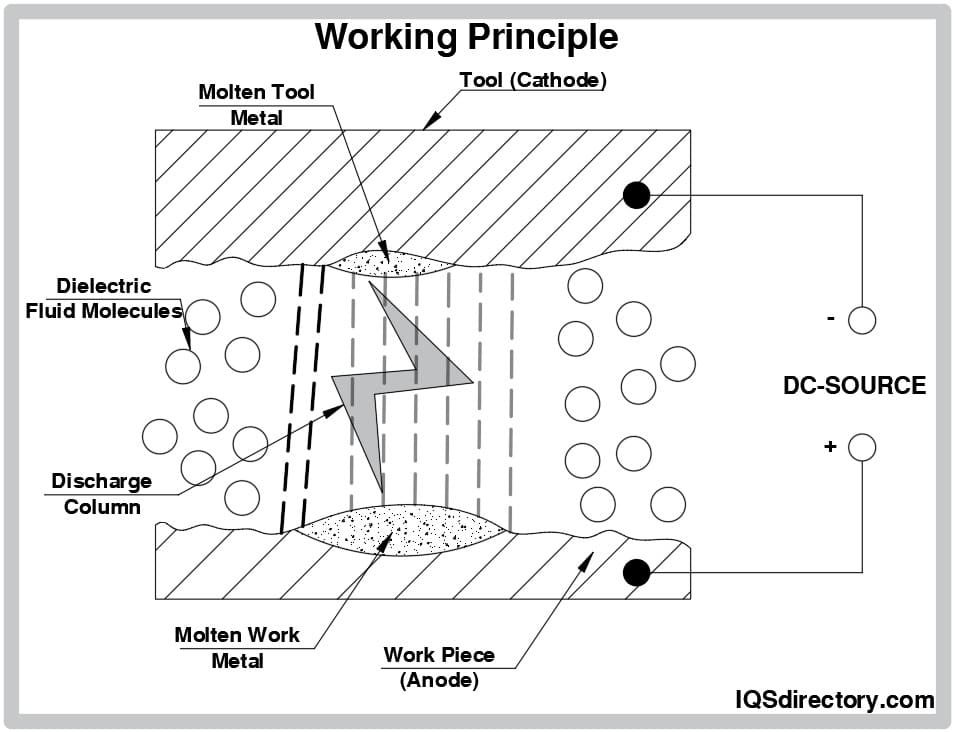

In EDM, the workpiece is cut (eroded) using an electric spark as the cutting tool to create the finished item in the desired shape. Then, like a lightning strike hitting a tree before it strikes the ground, electricity strikes the workpiece's points of least resistance as it travels through the electrode as a square wave.

The material is removed from the workpiece through a series of quickly repeated current discharges occurring between two electrodes exposed to an electric voltage and separated by a dielectric liquid. The tool-electrode, also known as the tool or electrode, is one of the electrodes, and the workpiece-electrode, also known as the workpiece, is the other.

The increases in the electric field's intensity between the two electrodes results in a voltage rise, which causes the liquid's dielectric properties to break down causing an electric arc.

Types of EDM Machining

There are two types of EDM machining, which include:

- Die Sink EDM

- Wire EDM

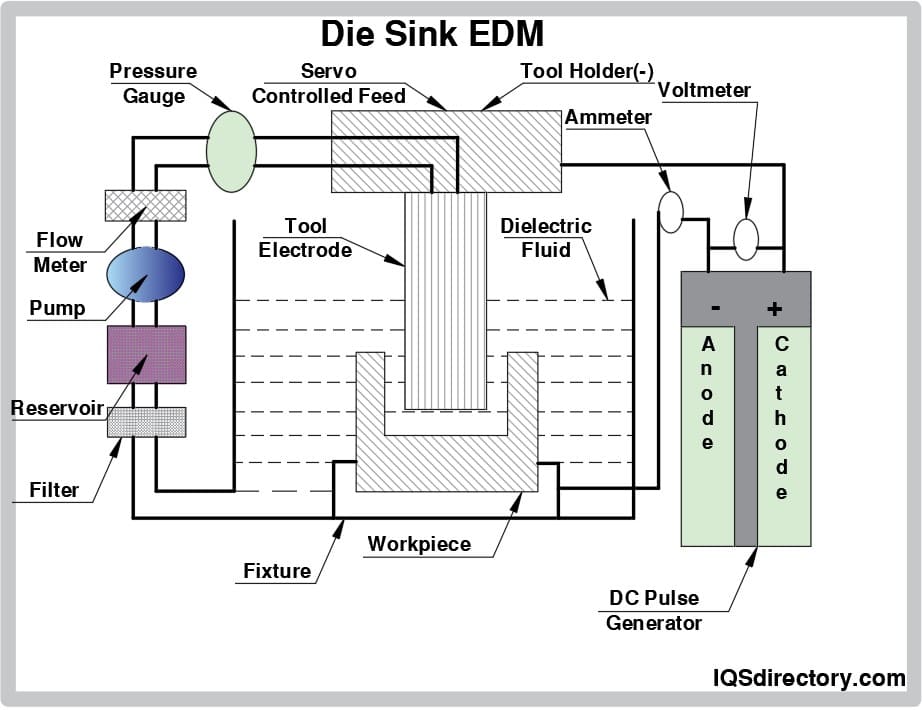

Die Sink EDM

Die sinking EDM is a process in which the electrode tooling workpiece and an insulator, light oil, are both submerged in a fluid that is always running to maintain the temperature of the workpiece. Additionally, the dielectric fluid washes out hard material that has vaporized. Bringing both the metal workpiece and copper electrode (a conductive material) within a small range apart causes a high voltage spark to jump from the electrode onto the workpiece and discharge them between the closest points on the workpiece and the electrode, which is the spark gap (known as sparking).

EDM produces an even, continuous, high-quality surface finish with great accuracy without requiring any pressure energy during the operation. Afterward, the electrode would be lowered into the workpiece in a spiral pattern at a rate determined by the desired surface finish texture, ensuring that vaporized material would be flashed away from the cutting area.

This step enables efficient material removal from the machine and brings the EDM machining process to a successful conclusion with the final desired shape of the part. After being charged by the high voltage required for heat treatment during the production process, the dielectric fluid in the EDM machine tool also permits a static discharge.

Wire EDM

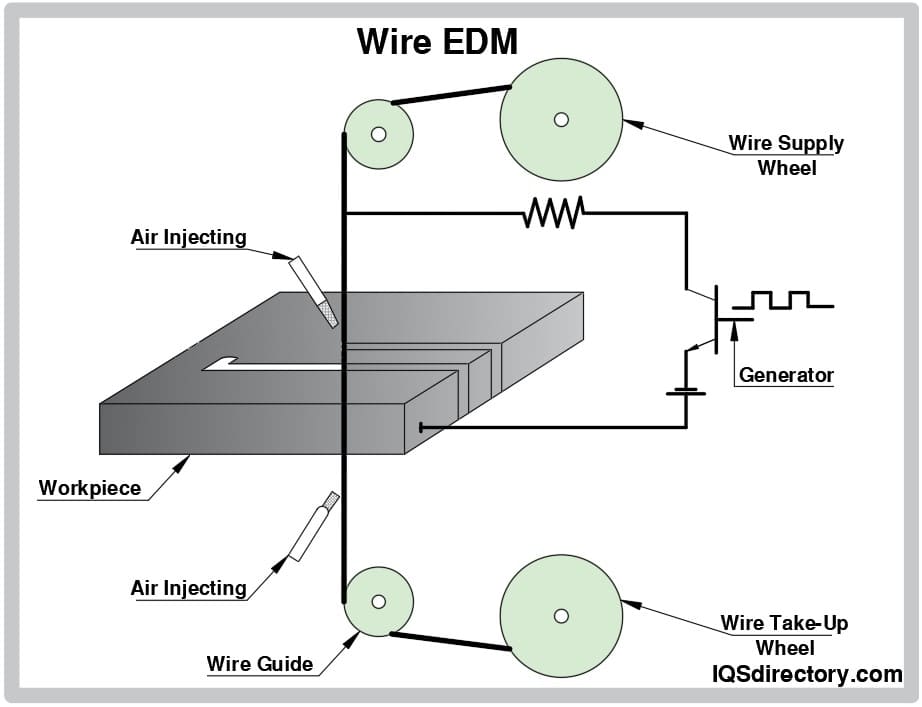

A graphite wire electrode is passed between the supply spools in wire EDM (wire erosion), which holds the EDM wire in tension to cut straight lines. A high voltage is charged for heat treatment, and as the thin wire passes through the workpiece, it is discharged.

As a result, the metal workpiece's smallest gap (or small hole) generates hundreds of sparks each second. Regularly replacing the EDM-damaged graphite electrode brought on by electrode wear maintains high precision throughout the wire EDM process. Deionized water is used as an insulator during the entire EDM machining process, flushing the conductive material and recycling it through a filter system while continuously running.

The upper thin wire guide can be translated along the X- and Y-axes to support cutting angles up to 30°. This enables the wire EDM machines to cut both internal and external profiles, something with which CNC turning & CNC milling struggle.

Advantages of EDM Machining

Among the benefits of EDM are:

- It is possible to create tapered holes.

- Whereas conventional cutting tools may destroy the item with too much cutting tool pressure, very small workpieces can be machined.

- It is possible to achieve a good surface finish, and redundant finishing routes may even result in a very good surface finish.

- internal pipe or container corners and curves down to R.001"

- Very small holes are possible.

- machining of highly hard materials with exceedingly tight tolerances

- ability to machine intricate designs that would be challenging to create with traditional cutting tools

- The tool and the workpiece do not come into direct touch. Thus, weak materials and sensitive portions can be machined without visible deformation.

Disadvantages of EDM Machining

- During machining, excessive tool wear takes place.

- The usage of combustible oil-based dielectrics may present a fire risk.

- Locating knowledgeable machinists is difficult.

- Electrically non-conductive materials can only be machined using a specialized process setup.

- Because of electrode degradation, it is difficult to replicate sharp edges and overcut then develops.

- Power usage per unit is relatively high.

- the extra effort and expense required to make electrodes for ram/sinker EDM

Choosing the Correct EDM Machining Company

To ensure you have the most positive outcome when selecting an EDM machining business, it is important to compare several EDM machining companies using our directory of EDM machining companies. Each EDM machining company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each EDM machining company website using our proprietary website previewer to learn what each company specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services