The electrothermal production process called wire EDM (Electrical Discharge Machining) uses a thin, single-strand metal wire and de-ionized water to cut through metal while preventing rust. Since the wire and the workpiece are not in direct contact during the wire-cutting process, the material’s shape and the wire’s course can be machined without being altered. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

Our job shop offers electrical discharge machining (EDM). At Quad Precision Tool, our reputation of manufacturing tooling to exacting specifications is unexcelled. We machine conductible materials using wire EDM & conventional/CNC sinker EDM. We also do high speed EDM drilling & micro-hole drilling.

At Wire EDM Solutions LLC, we offer a variety of EDM services to meet our customer’s needs. We have experience serving a wide range of industries including aerospace, automotive, defense, medical, and power generation markets. Our team is dedicated to providing top quality customer service and flexible lead times at extremely competitive costs. To learn more about what we do, contact us today!

C & H Machine, with 12 late-model EDM centers and several machining centers, is a full-service job shop able to jump on your one-piece rush while maintaining your high-quantity production schedule. C & H Machine offers wires, sinkers and drilling, along with milling, turning and welding.

More Wire EDM Companies

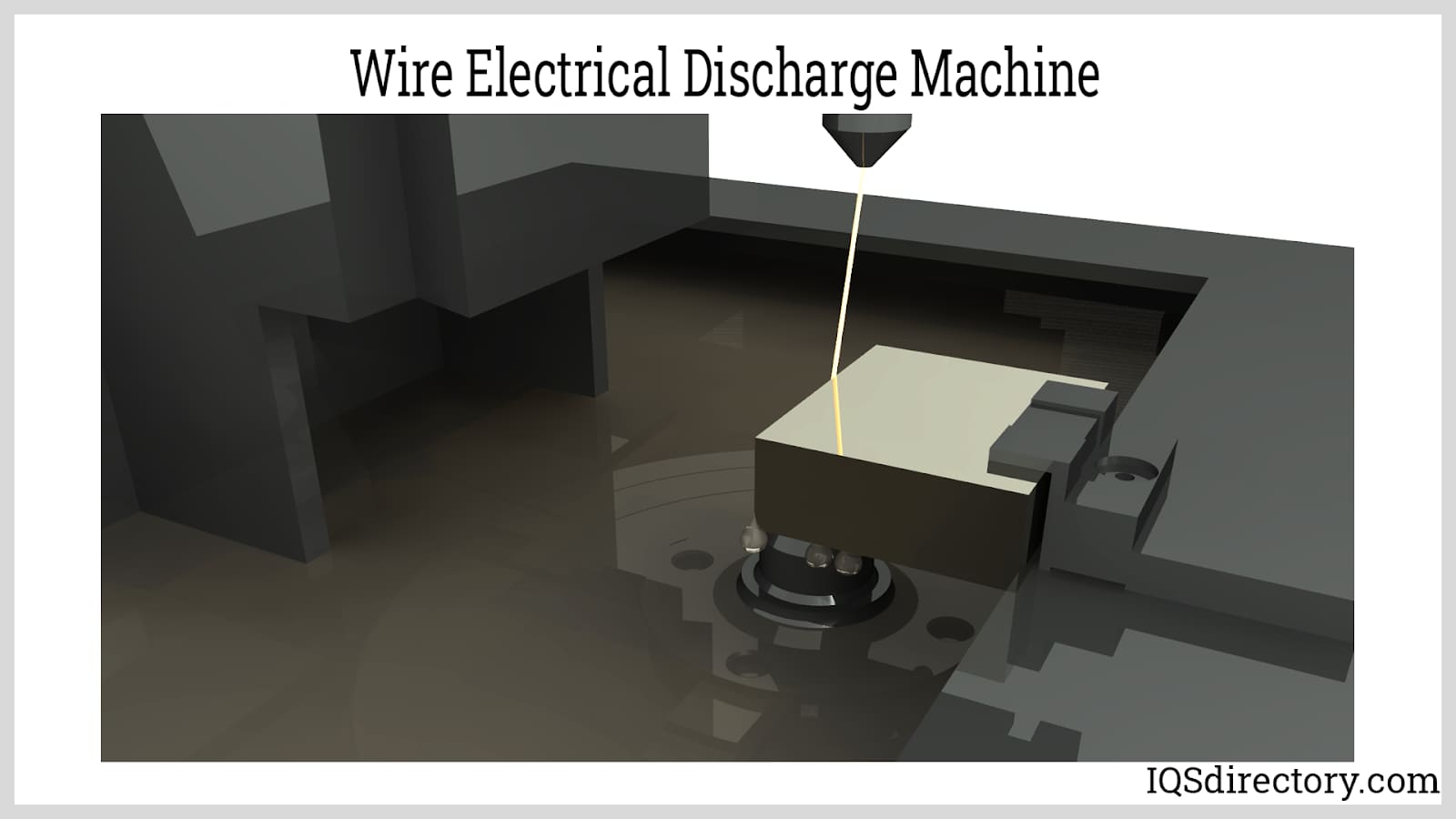

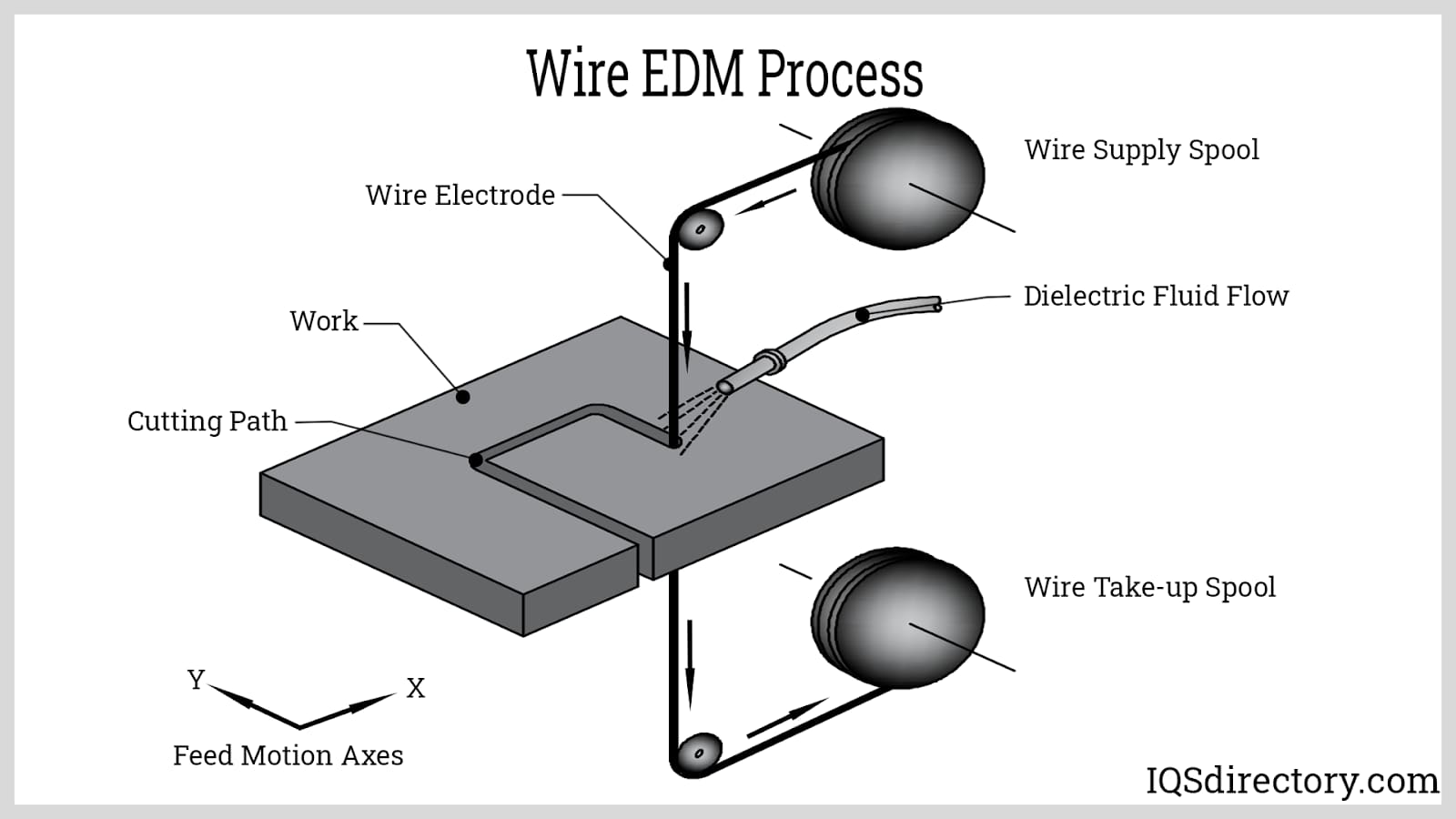

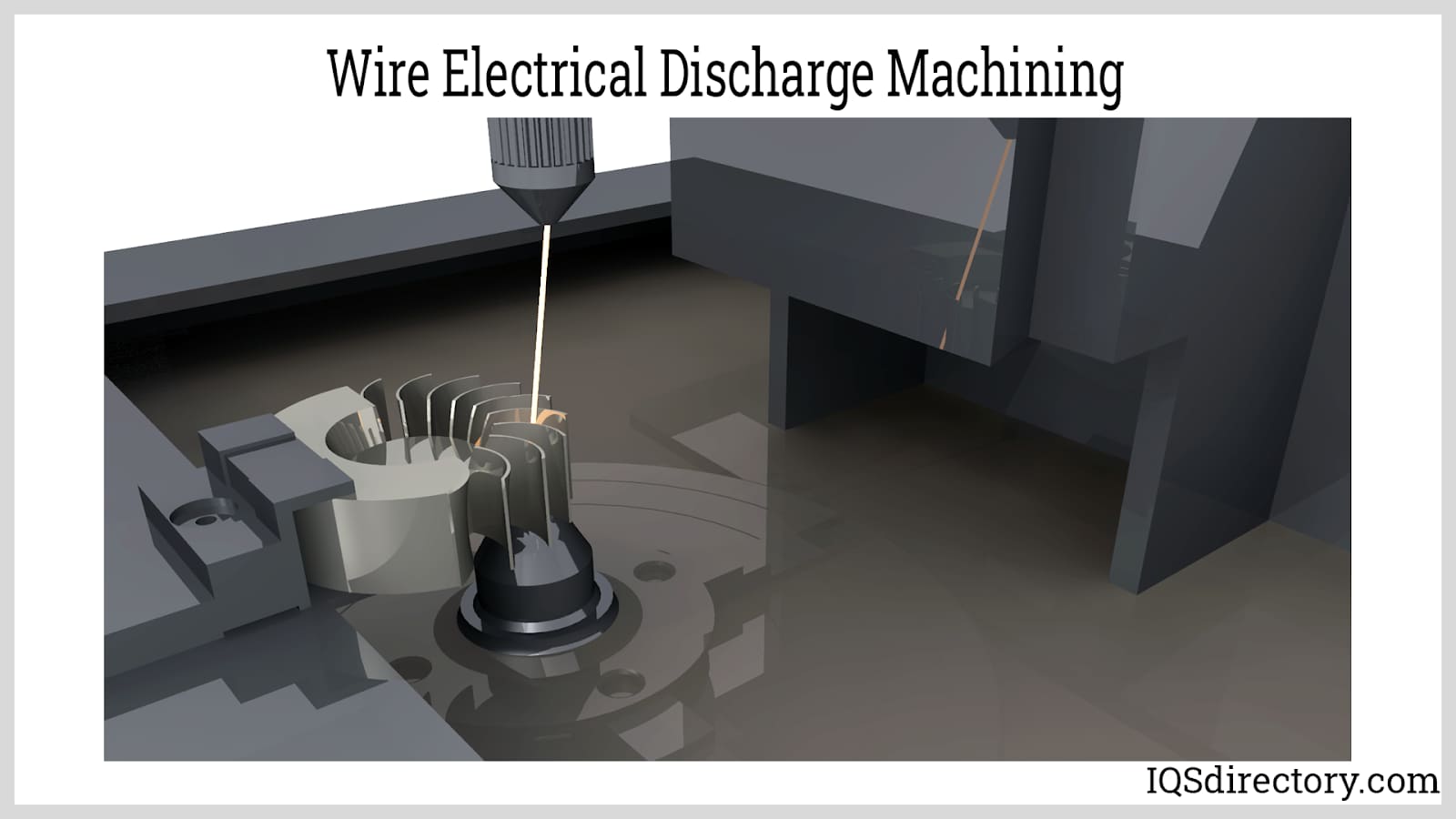

The wire is very quickly charged to the desired voltage to do this. De-ionized water surrounds the wire as well. A spark jumps the gap when the voltage is at the proper amount, melting a small workpiece area. The de-ionized water cools and removes the tiny particles from the gap by flushing them out. As a result, the workpiece material's hardness has no negative impact on the cutting speed. Wire cutting is frequently used to manufacture extrusion dies and blanking punches. In wire electrical discharge machining (WEDM), a thin electrode wire that follows a precisely programmed path is used to cut or shape a workpiece, frequently made of conductive material. Although smaller and bigger sizes are available, electrodes typically have diameters between 0.004" and 0.012" (0.1 mm and 0.3 mm).

How WEDM works

An EDM machine always cuts the entire workpiece. A hole in the workpiece is required before beginning wire machining, unless the process starts from the edge. Each discharge on the machining region leaves a crater in the workpiece and an impression on the tool. It is possible to create pieces with taper or various profiles at the top and bottom thanks to the wire's ability to incline. The electrode and workpiece never make contact mechanically (see above).

The wire typically has a diameter of between 0.1 and 0.3 mm and is constructed of brass or layered copper. Depending on the accuracy and surface polish required, a part may be cut, roughed, or skimmed. On a single cut, the wire should ideally go through a solid component before dropping a slug or piece of scrap. This will provide adequate accuracy for some tasks, but skimming is usually required.

Components of WEDM

- CNC Tools -CNC tools manage the entire Wire EDM machining process. Controlling the entire procedure entails being able to handle the cutting process automatically and sequence the wire path.

- Energy Source -The power supply unit is the part that sends pulses to the wire electrode and the workpiece. It also regulates the quantity and intensity of electrical charges that travel through the wire electrode and come into contact with the workpiece.

- Wire -To produce the electrical discharge, the wire acts as the electrode. The workpiece's thickness and form directly impact the wire's diameter. Typically, wires with sizes between 0.05 and 0.25 mm can be used.

- The most common types of wires include:

- Dielectric Medium -Dielectric fluid must be present in the tank where the wire-cut EDM procedure is performed. With the help of this liquid, the workpiece's minute particles are kept from adhering to the wire electrode. De-ionized water is the most used medium since it cools the process and produces a workpiece with a smooth surface.

- Electrodes -The wire (cathode) and the workpiece serve as the machine's electrodes (anode). The servo motor controls the wire electrode, ensuring that it never makes contact with the workpiece while cutting with wire EDM.

Materials That Can Be Cut Using EDM Wire

The EDM wire method can cut any conductive material, including steel, titanium, aluminum, brass, and superalloys. Due to its accuracy, the EDM wire-cut technology has established itself as a standard cutting method across all industries. EDM wire makes cutting and creating metal machine parts, logos, and other objects simple. The thickness, dimension, and length of the item to be cut determine how much EDM wire will be needed to produce the part or its prototype.

Applications of WEDM

Many industries employ wire EDM machining because it is adaptable and can cut both ferrous and non-ferrous metals. Additionally, because it can process lengthy and extremely small pieces, size and shape allow its use. But because the thickness of the wire electrode influences the use of a wire EDM machine, conventional EDM may work with harder and thicker materials.

Advantages of WEDM

- Create patterns or designs that would be difficult to make with traditional cutting tools, whether simple or complex.

- CNC-controlled cutting patterns can be quickly finished on various stainless steel alloys while keeping a low Ra surface roughness.

- High dimensional accuracy for pieces that fit together tightly

- The procedure produces a few burrs.

- Typically, custom tooling is not required.

Choosing the Correct Wire EDM Company

For the most positive outcome when selecting a wire EDM company, it is important to compare several businesses using our directory of wire EDM businesses. Each wire company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each wire EDM business website using our patented website previewer for an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple wire EDM companies with the same form.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services