Hard materials are frequently machined using the non-conventional process known as electrical discharge machining (EDM). This technique is well-liked since EDM can work with all materials, regardless of how hard they are. Modern engineering materials used in harsh environments are frequently molded or created through the Electrical Discharge Method technique. However, this method has its shortcomings. Low material removal rates and substantial tool wear can frequently reduce the effectiveness of this kind of machining. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

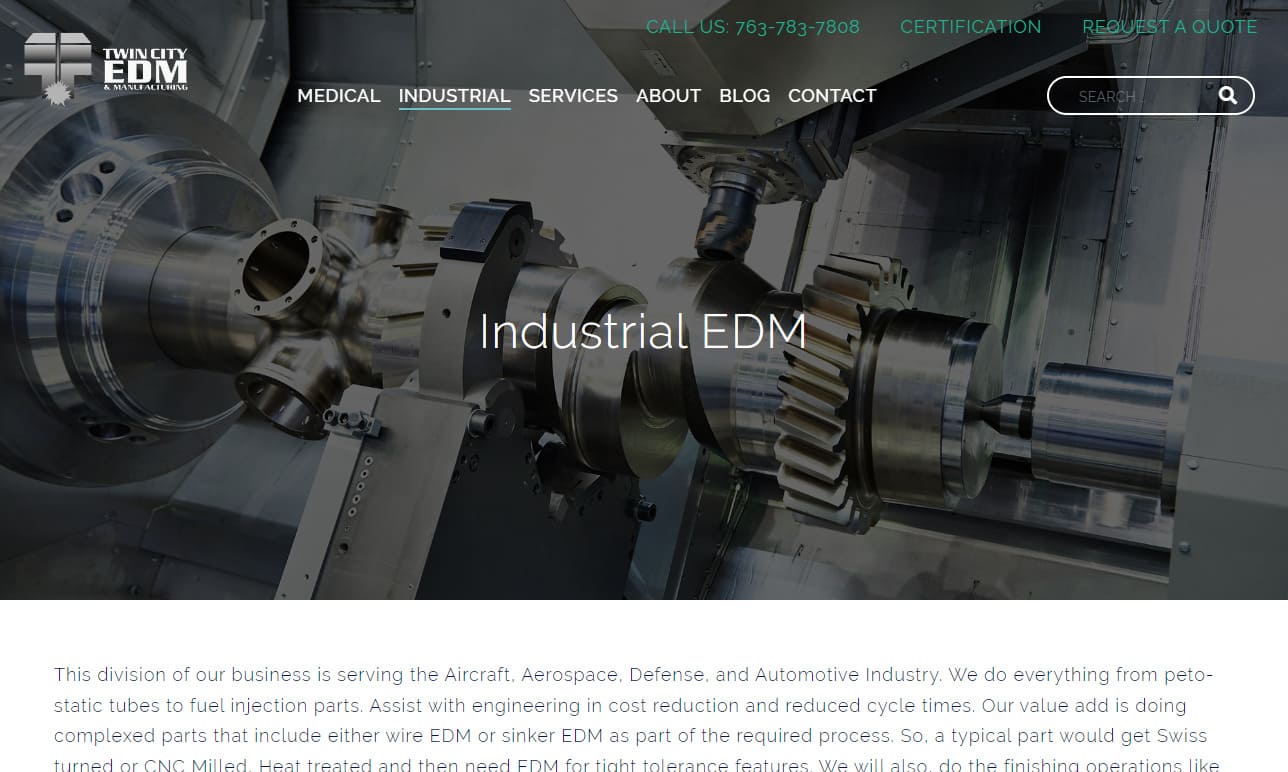

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

Our job shop offers electrical discharge machining (EDM). At Quad Precision Tool, our reputation of manufacturing tooling to exacting specifications is unexcelled. We machine conductible materials using wire EDM & conventional/CNC sinker EDM. We also do high speed EDM drilling & micro-hole drilling.

At Wire EDM Solutions LLC, we offer a variety of EDM services to meet our customer’s needs. We have experience serving a wide range of industries including aerospace, automotive, defense, medical, and power generation markets. Our team is dedicated to providing top quality customer service and flexible lead times at extremely competitive costs. To learn more about what we do, contact us today!

C & H Machine, with 12 late-model EDM centers and several machining centers, is a full-service job shop able to jump on your one-piece rush while maintaining your high-quantity production schedule. C & H Machine offers wires, sinkers and drilling, along with milling, turning and welding.

More Electrical Discharge Machining Companies

EDM can be integrated with other traditional or unconventional manufacturing techniques to produce a more homogeneous and balanced machining setup. The inherent shortcomings of the EDM technique can be overcome by hybrid or mixed approaches to machining. When combined with traditional production processes, additional manufacturing techniques can considerably increase machining performance in EDM.

Working Principle of EDM

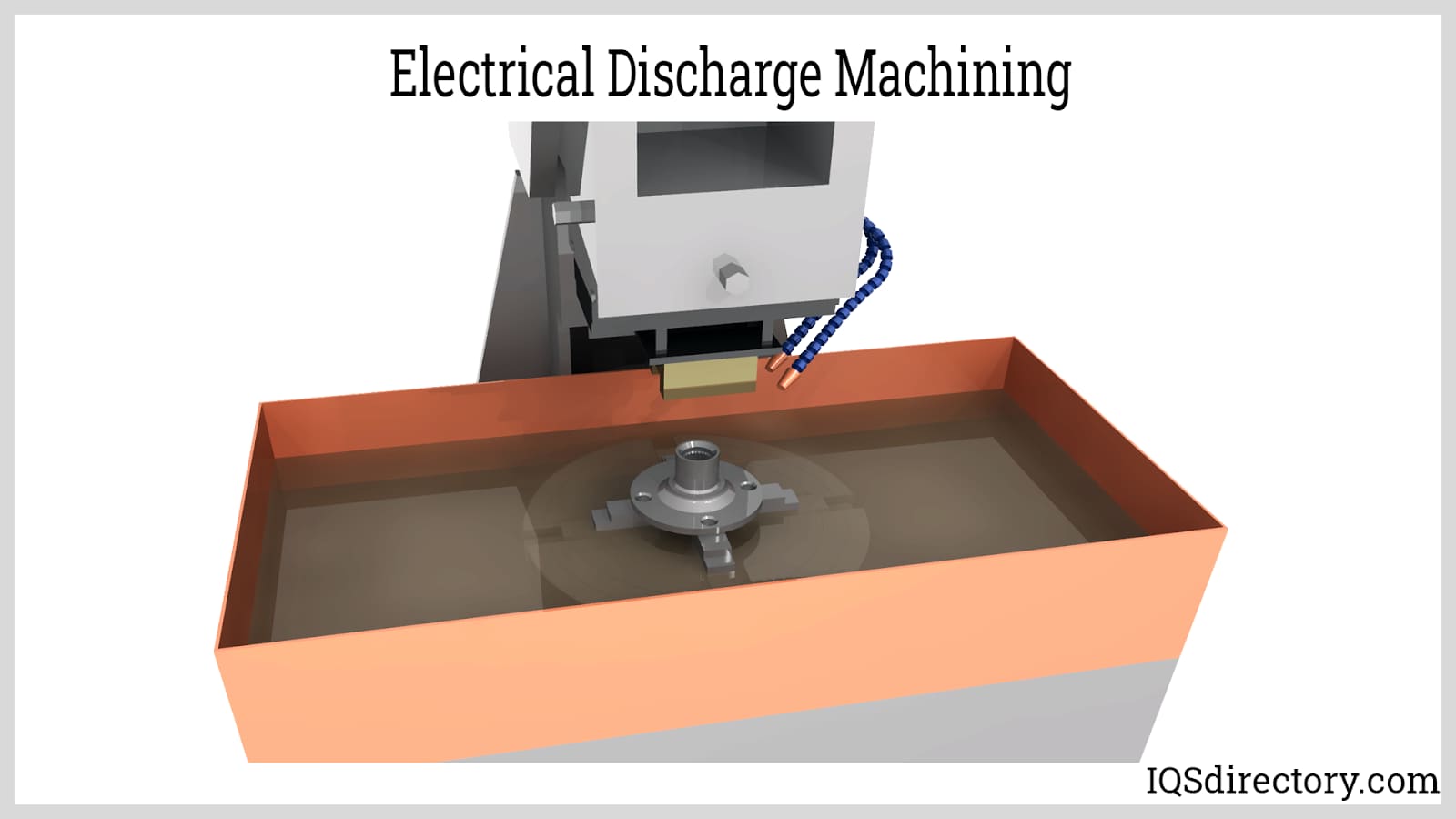

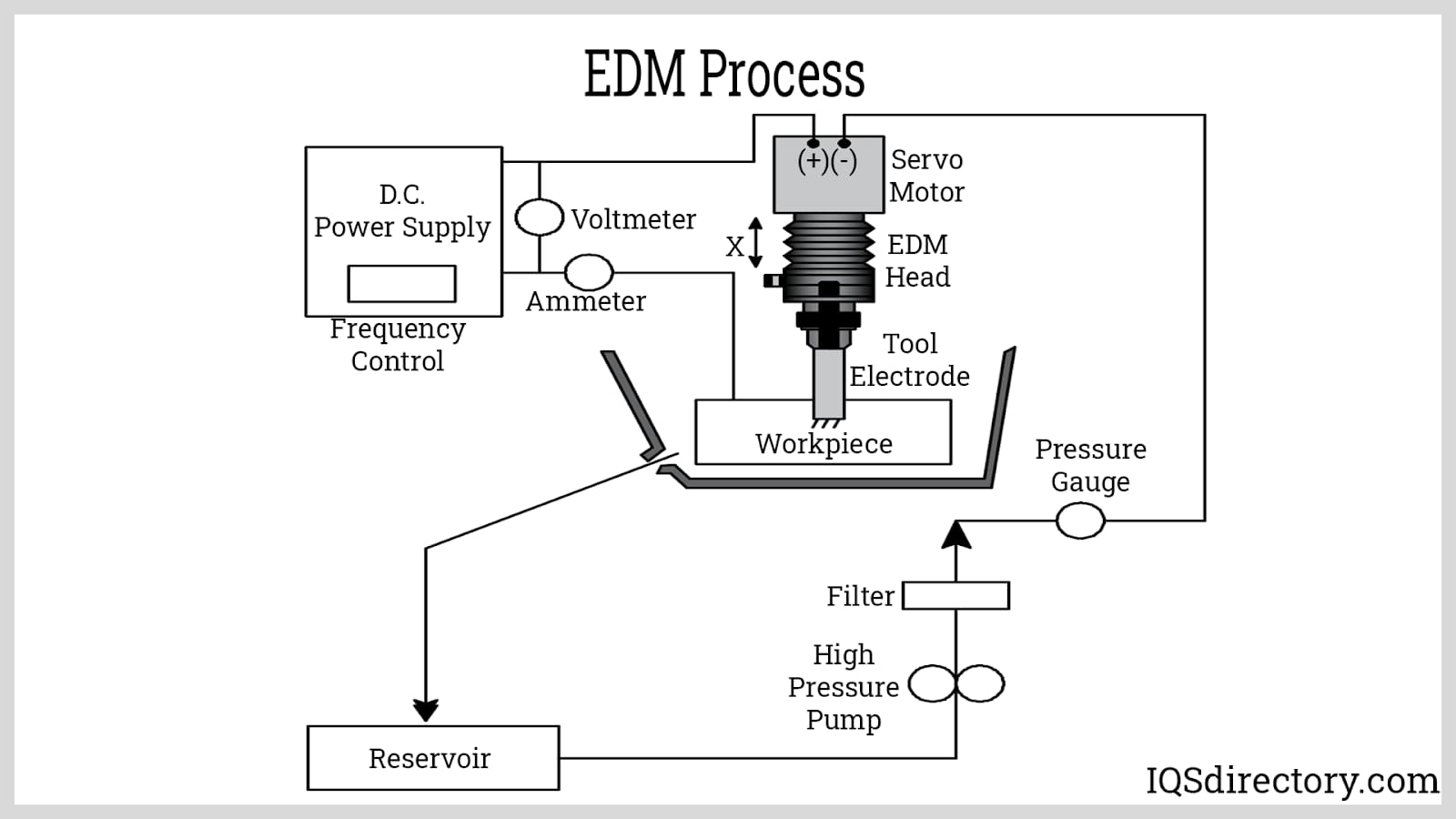

Spark creation and metal removal through spark erosion are the foundations of the electrical discharge machining working method. When an electric spark strikes a piece of metal and burns a hole, that is exactly what happens with EDM spark erosion. This process produces heat, which leads to the erosion and evaporation of metal. Therefore, the workpiece and the tool used in this machining process must be constructed of conductive materials.

Components of EDM

Power generator

This is how the EDM machining process is powered. The power generator is linked to the negative terminal, while the machined component is attached to the positive terminal (i.e. the workpiece). Electrical discharge machining uses a variety of power generators, some of which are listed below:

- Resistance-capacitance type generator (RC type) generator of relaxation

- Rotary type generator

- Electrical pulse generator

- EDM hybrid generator

Workpiece

The item to be machined is known as a workpiece. It is attached to the positive terminal of the power supply and fastened in the dielectric container using a fixture.

Fixture

The workpiece is held securely in the dielectric container using the fixture.

Dielectric Medium

The operation of the EDM Machining process depends heavily on the dielectric medium. The dielectric fluid is typically a low-viscosity hydrocarbon oil. The electrode and the workpiece are kept apart by the dielectric. As the spark is created during the EDM machining procedure, the dielectric is ionized to create a column or path in the tool, which causes a surge of current. When the distance between the tool and work gap reaches about 0.03 mm and a voltage of about 7V, the dielectric medium is raptured. The spark discharge will occur in a very small area at a temperature and pressure of about 10,000 °C. Each spark experiences this in a matter of a microsecond. A very small portion of the workpiece vaporizes as the arc is driven out as the column of ionized dielectric vapor compresses. The minuscule metal particles are cooled to form small spheres, which are swept away by the dielectric fluid's flux.

Types of EDM methods

Wire EDM

Wire EDM is a common procedure that is also referred to as wire erosion or spark EDM. The workpiece is sliced with a brass wire or a thin copper wire. The electrode, in this instance, is a tiny wire. In this instance, deionized water typically serves as the dielectric fluid. The wire is continuously unfurled from an automatic feed using a spool during the procedure. This is due to the possibility that the wire and workpiece could compromise the electrical discharge. A new discharge path is therefore required in the cut. This strategy performs admirably. Engineers must take care that the wire must entirely passes through the workpiece. In essence, it, therefore, makes two-dimensional cuts in three-dimensional components.

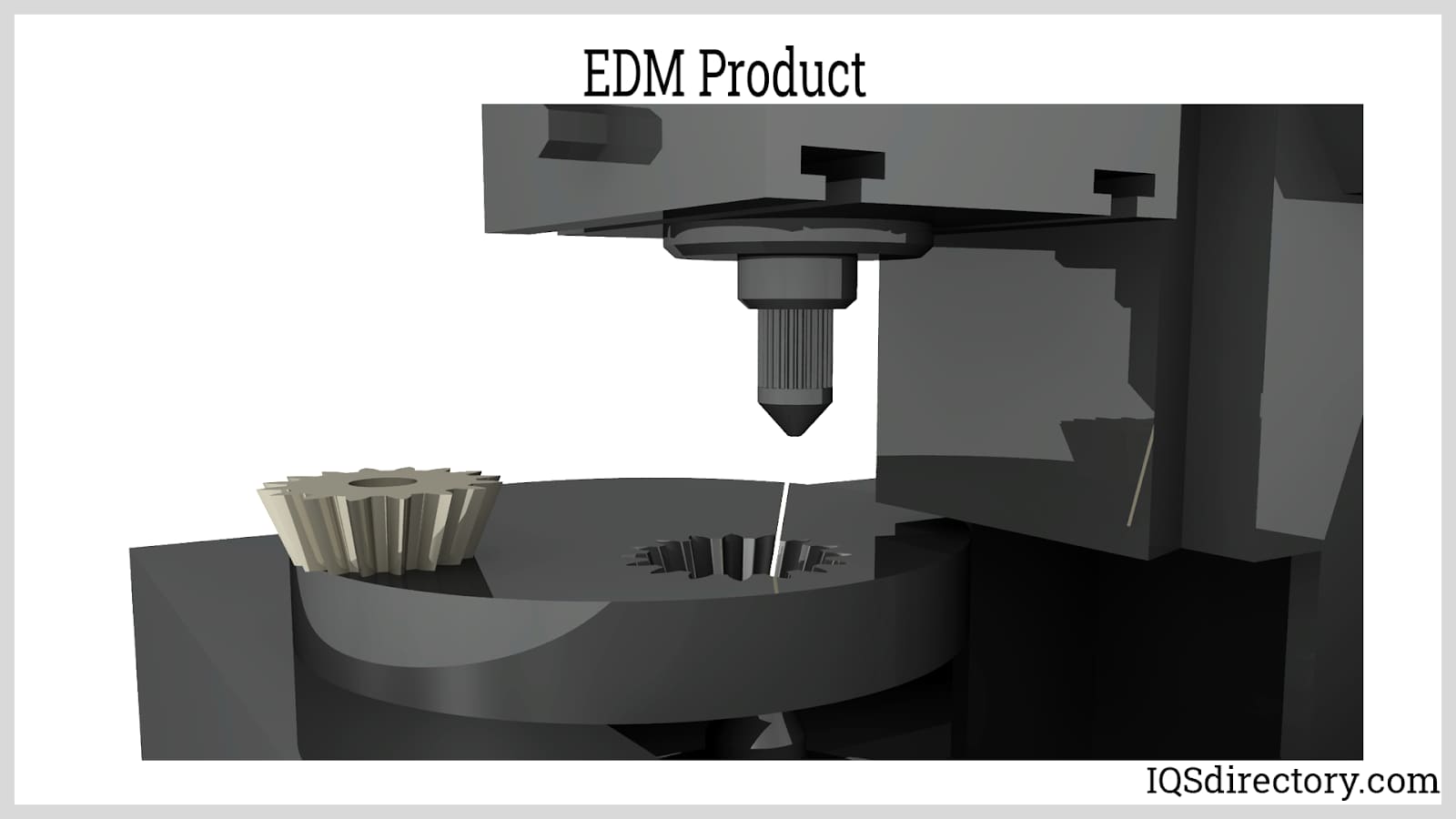

Sinker EDM

This procedure creates a positive of the desired shape using electrodes made of pre-machined copper or graphite. Next, the electrode is pressed into the workpiece to make a negative of the original material shape. Several variables may influence the choice of electrode material in sinker EDM. These include the electrode's resistance to erosive wear and its conductivity, with copper material often more difficult to process than graphite. However, copper is better and more robust.

Hole EDM

In contrast to standard drilling methods, hole Electrical Distribution Machining may produce exceedingly tiny and deep holes. Furthermore, these holes don't require deburring. Regardless of the nature or hardness of the metal, this approach drills precise holes more quickly than conventional techniques.

Applications of EDM

- Machining

- Injection molding

- Die casting

- Small hole drilling

Advantages of EDM

- Any hard material, even one that has been heat-treated, can be machined with EDM.

- The tool can be used to create intricate shapes that can be duplicated.

- A great degree of accuracy, roughly 0.005 mm, can be attained.

- Up to 0.2 microns of good surface quality can be attained economically.

- The length of the machining process is the same as that of traditional machining.

- This method does not create mechanical tensions (the tool and work do not have contact).

- Proper cooling and lubrication extend the tool’s life.

- On the dies, it is simple to create hard surfaces that are also resistant to erosion.

- Any electrically conductive material can use it.

Choosing the Correct Electrical Discharge Machining Company

For the most productive outcome when selecting an electrical discharge machining company, it is important to compare several businesses using our directory of electrical discharge machining companies. Each company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each electrical discharge machining company website using our proprietary website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services