Many different terms, including ram EDM, cavity EDM, volume EDM, and conventional EDM, refer to sinker EDM. Spark erosion is used in sinker EDM, a subtractive manufacturing technique, to create extremely precise parts. Spark erosion is the hollowing out of metal workpieces using an electrode-shaped tool. The electrode sinks into the raw material, giving sinker EDM its name. Machines that operate horizontally or at any other angle are also a possibility. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

Our job shop offers electrical discharge machining (EDM). At Quad Precision Tool, our reputation of manufacturing tooling to exacting specifications is unexcelled. We machine conductible materials using wire EDM & conventional/CNC sinker EDM. We also do high speed EDM drilling & micro-hole drilling.

At Wire EDM Solutions LLC, we offer a variety of EDM services to meet our customer’s needs. We have experience serving a wide range of industries including aerospace, automotive, defense, medical, and power generation markets. Our team is dedicated to providing top quality customer service and flexible lead times at extremely competitive costs. To learn more about what we do, contact us today!

C & H Machine, with 12 late-model EDM centers and several machining centers, is a full-service job shop able to jump on your one-piece rush while maintaining your high-quantity production schedule. C & H Machine offers wires, sinkers and drilling, along with milling, turning and welding.

More Sinker EDM Companies

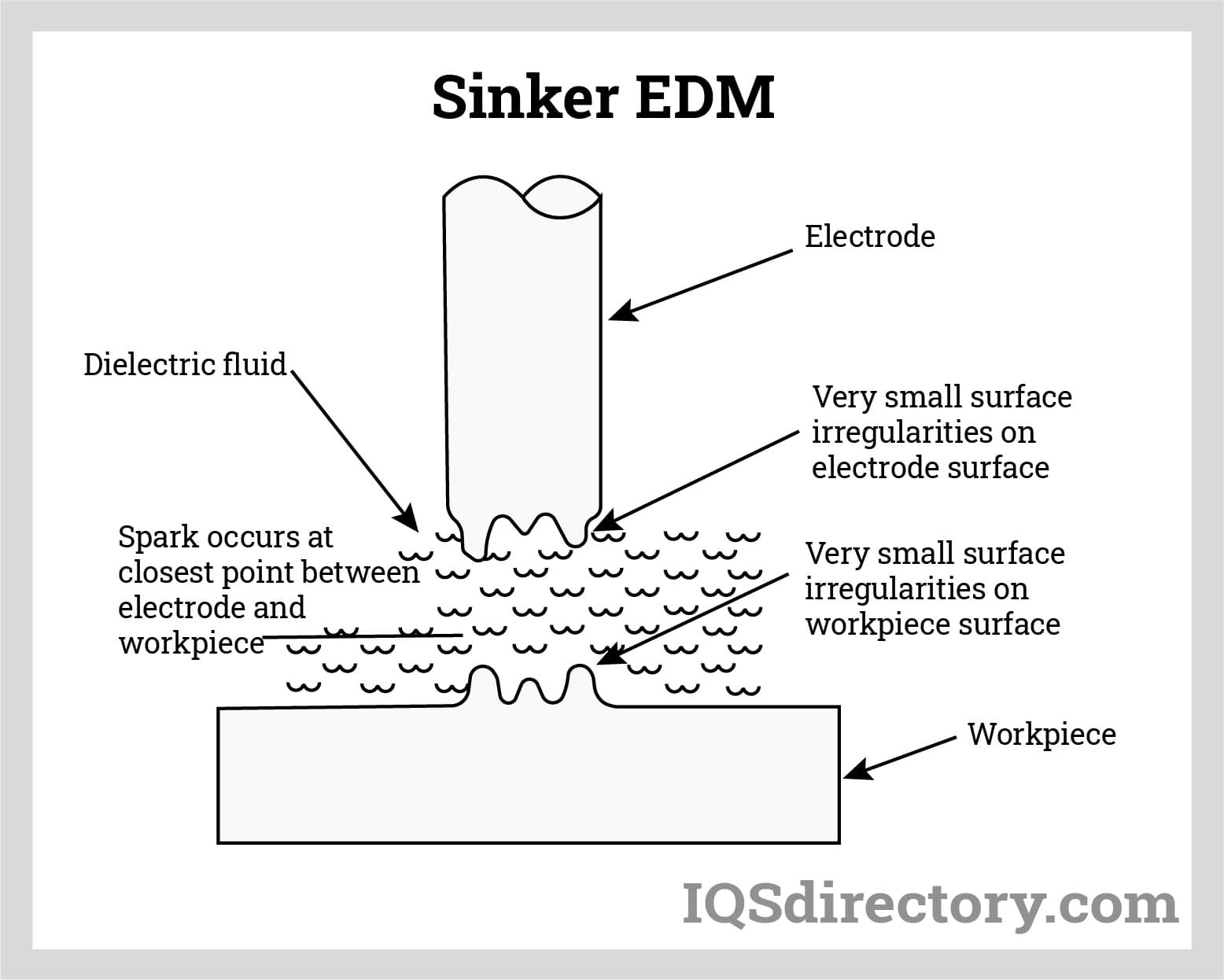

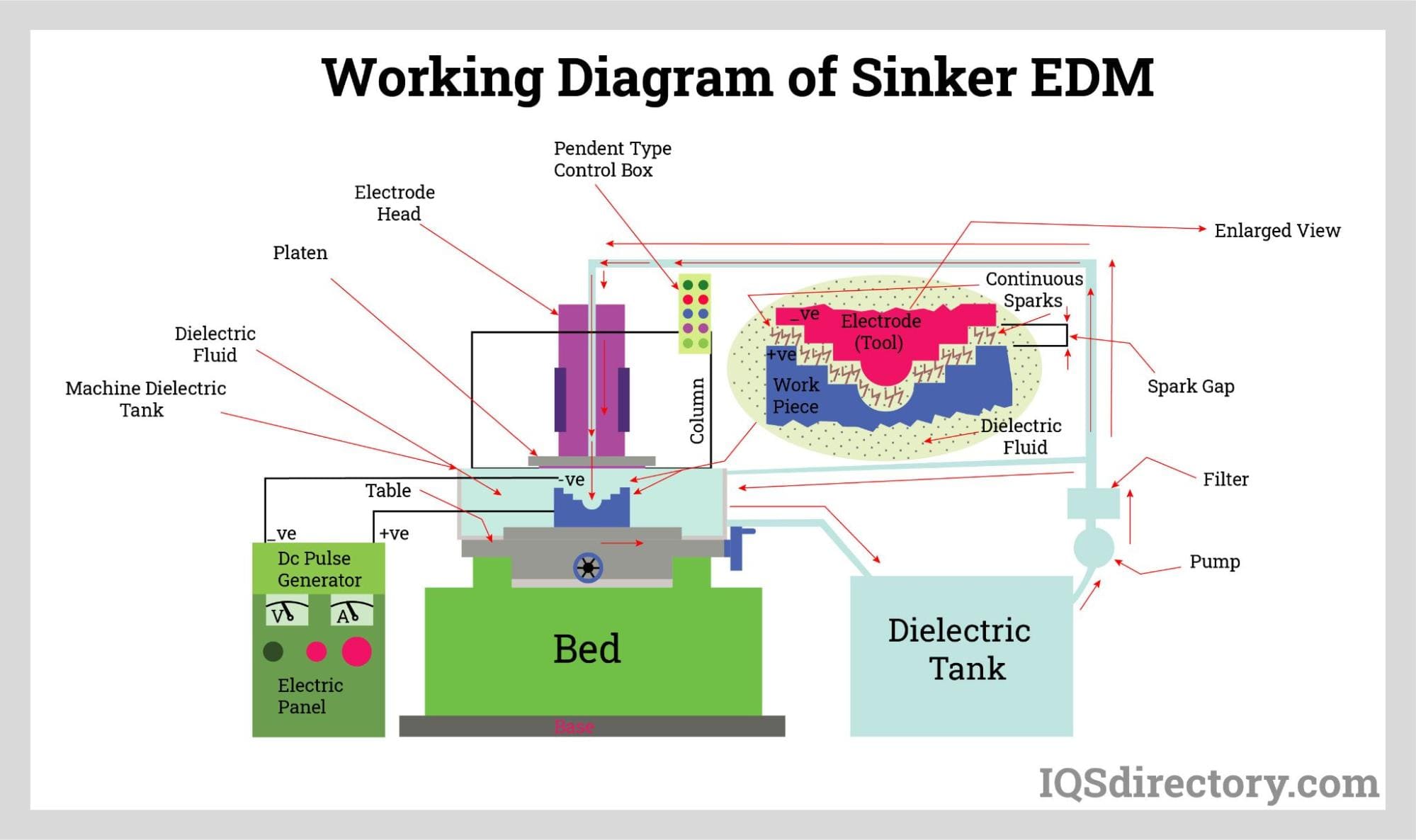

The workpiece-electrode (workpiece) and the tool-electrode (electrode) are steadily brought together until they practically touch. The nearest workpiece material is subsequently melted away by a high-voltage spark (EDM pulses) between the electrode and the workpiece, allowing the electrode to carve out the required shape in the workpiece. It works well for creating blind voids in conductive metals.

How Does Sinker EDM Work?

The electrodes are typically manufactured from diverse materials that will match certain metals and alloys inside the material. The material is immersed in oil, preventing debris from sticking to the surface. The base metal will have been eroded, exhibiting a specific design like an engraving once the procedure is finished and all extra pieces have been removed.

Both the electrode and the source material can be positively or negatively charged. Electric sparks fly between the two every time the electrode approaches the component. The temperature created by this spark can increase locally to between 8,000 and 12,000° C. The electrode’s metal vaporizes locally due to the high temperature. The metal electrode is eroded as the other electrode descends into the component. Any conductive material can be subjected to the sinker EDM technique; the substance's hardness is irrelevant.

Types of EDM Electrode Materials

Depending on the application’s requirements, alloys have qualities that offer various advantages. For example, material for an electrode should be able to:

- Transfer the electric pulses to the surface of the workpiece for efficient spark erosion and minimal electrode erosion.

- Be adopted for techniques like casting and machining.

- Maintain an excellent surface finish when machining and resist tool wear (electrodes with a good surface finish create items with a better surface finish in EDM).

- Ensure a high metal removal rate.

Copper is a typical base material due to its strength and good conductivity. It is helpful in applications requiring a fine finish or the EDM machining of tungsten carbide.

Copper tungsten materials are tungsten and copper composites. When flushing is difficult, copper tungsten helps create deep grooves. It is also good for tungsten carbide EDM machining.

Graphite at low speeds gives a cleaning action.

Silver tungsten material is a silver matrix that contains tungsten carbide particles. High electrical conductivity is provided by silver, and excellent erosion resistance and good anti-welding properties are provided by tungsten in high-power applications. Consequently, this composite is ideal for EDM electrode applications where maximizing conductivity is important.

Brass is made up of zinc and copper. The material for sinker EDM has the advantage of being simpler to process and having brass that can be die- cast to provide certain electrodes.

Tellurium copper is beneficial for applications demanding a fine finish in EDM machining. Tellurium copper is more easily machined than copper, and its machinability is comparable to brass.

Molybdenum has strong tensile strength and good electrical conductivity, making it perfect for demanding applications that call for small-diameter wire. Molybdenum EDM wires are utilized for applications demanding exponentially small radii and small slot work.

Applications of Sinker EDM

Applications of sinker EDM include:

- Mold making

- Sharp inside corners

- Rapid Tooling

- Dies

- Injection molding molds

- Blind cavities

- Threads

- Internal splines

- Fine details

- Deep and thin ribs

- Blind keyways

Advantages of Sinker EDM

Some key advantages of sinker EDM are listed below:

- Accurate: If the electrode is accurately machined, sinker EDM can produce features with extremely high accuracy.

- Blind Cavities: Blind holes with unusual forms, such as hexagonal holes, can be produced via sinker EDM.

- Simple Tooling: Sinker EDM does not need a tougher tool than the machined material, unlike other machining techniques. Sinker EDM can be used to manufacture conductive metals.

Disadvantages of Sinker EDM

The disadvantages of sinker EDM are listed below:

- Slow: Comparing the sinker EDM technique to other machining methods like CNC milling, relatively little material is removed.

- High Operating Costs: Sinker EDM machines require excessive electricity since they use a high-energy form of spark erosion.

- Limited to Conductive Material: Plastics and composites cannot be machined by sinker EDM machines since they can only work with conductive materials.

Choosing the Proper Sinker EDM Business

For the most beneficial outcome when selecting a sinker EDM company, it is important to compare several businesses using our directory of sinker EDM companies. Each sinker EDM company has a business profile page illustrating their areas of experience and capabilities, and a contact form to directly communicate with the business for more information or request a quote. Review each sinker EDM company website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple sinker EDM companies with the same form.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services